INTEGRATED PRODUCTION

Aircraft engine parts and precision parts for the aerospace industry●Thoroughly managed Quality and Just in time delivery through the integrated production process

●Granted NADCAP accreditation for Aircraft Quality System and Non-destructive testing (PT)

●Improve flexibility and reliability of various processes through a unique industrial consortium in Japan

* The above is an example.

Collaboration with cooperating companies enabling our flexibility and reliability of various processes.

Nadcap Accreditation

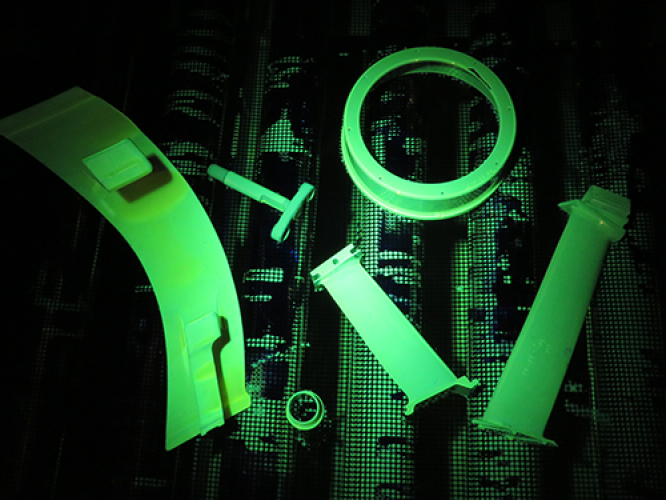

Penetrant Testing

JASPA Co., Ltd. holds Nadcap accreditation for Penetrant testing (PT*) and it’s aircraft quality system. Components up to 1.5m in diameter can be inspected.

Besides PT to NAS 410 at our Niigata factory, we are able to offer general NDT inspection for Magnetic particle testing (MT), Eddy current testing (ET) and Ultrasonic testing (UT) or Ultrasonic thickness gauging (UTG).

This can be arranged at your location for MT, PT, ET , UT & UTG, if required.

The various methods mentioned can be used for finding surface breaking defects or subsurface defects.

Should you require any further information, please contact us.

* Penetrant testing, one of the methods of non-destructive testing, is highly sensitive to evaluate

discontinuities open on the surface and is widely used for inspection of aerospace components

■Penetrant testing equipment

| Name | Maximum work size | Applicable method |

| A Line | 1000(L)×1000(W)×500(H)mm | Method A |

| B Line | 1400(L)×1400(W)×550(H)mm | Method A, D |

| D Line | 1400(L)×1400(W)×550(H)mm | Method A, D |

■Magnetic particle testing bench

| Name | Maximum work size | Magnetization System |

| U20A | φ400×1300(L)mm | FWDC |

■ Radiographic testing equipment

| Name | Radiation area | Maximum output |

| MUJ450kV | φ1056mm | 450kV |

-nxf7zoybi2iod0482knht8985lsw25sbxc5okwvcao.jpg)

-1-1-nxnl79p7m8k28r7u79ovse29ap70vt17422az8zpj4.jpg)

-nxf7ztnig8p3z1xeb4omnp2j4j5q4nazlzf3zaodfk.png)

--nxf7zxev7ku99hrxp6b4xo4di2n6zfpwyi11weisqo.jpg)

前

次

MAIN FACILITY

(FMS available)

FMS (flexible manufacturing system)

前

次

COMPANY DATA

Company Name

JASPA Co., Ltd.

Head office

3rd floor,Kinoshita shoji Bldg,4-43 Masago-cho, Naka-ku, Yokohama city, Kanagawa, JAPAN

Niigata Factory

8460 Urushiyama, Nishikan-ku, Niigata city, JAPAN

Tel.+81-256-77-7333

Established

April 14, 2004

Capital

40 million JPY

President

Kazuyuki Abe

Directors

Keijiro Yamauchi

Koichi Yamauchi

Businesses

・Integrated production of aircraft engine parts and precision parts for the aerospace industry at joint factory

・Manufactured to Order

・Non-destructive testing

・Inspection services (3D precise measurement)

Employees

13 (NAS410 (PT) Level 2 inspector:4)

Company Name

JASPA Co., Ltd.

Head office

1317-3, Kamisugata-cho, Hodogaya, Yokohama city, Kanagawa, JAPAN

Niigata Factory

8460 Urushiyama, Nishikan-ku, Niigata city, JAPAN

Tel.+81-256-77-7333

Established

April 14, 2004

Capital

40 million JPY

President

Kazuyuki Abe

Directors

Keijiro Yamauchi

Koichi Yamauchi

Businesses

・Integrated production of aircraft engine parts and precision parts for the aerospace industry at joint factory

・Manufactured to Order

・Non-destructive testing

・Inspection services (3D precise measurement)

Employees

13 (NAS410 (PT) Level 2 inspector:4)